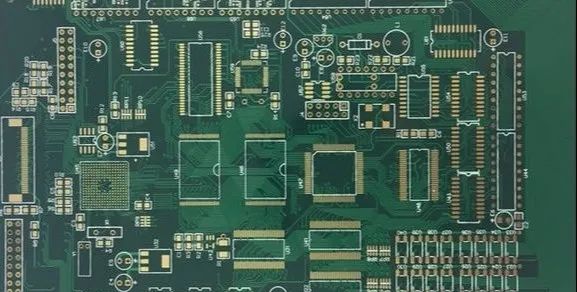

Kulondola kwapamwamba kwa bolodi loyang'anira dera kumatanthawuza kugwiritsa ntchito mizere yabwino m'lifupi / katayanitsidwe, mabowo ang'onoang'ono, m'lifupi mwake (kapena opanda mphete m'lifupi), ndi mabowo okwiriridwa ndi akhungu kuti akwaniritse kachulukidwe kake.

Kulondola kwakukulu kumatanthawuza zotsatira za "zoonda, zazing'ono, zopapatiza, zopapatiza" zidzabweretsa zofunikira zolondola kwambiri, kutenga m'lifupi mwake monga chitsanzo: 0.20mm mzere wa mzere, malinga ndi malamulo opangira 0.16 ~ 0.24mm monga oyenerera, cholakwika ndi (0.20±0.04) mm; ndi mzere m'lifupi mwake 0.10 mm, cholakwika ndi (0.1±0.02) mm chimodzimodzi. Mwachiwonekere kulondola kwa zotsirizirazi kumawirikiza kawiri, ndi zina zotero sizovuta kumvetsa, kotero kulondola kwakukulu kumafunika Sizikukambidwanso mosiyana, koma ndi vuto lodziwika bwino muukadaulo wopanga.

1.Fine waya zamakono

M'tsogolomu, m'lifupi / kachulukidwe kamene kadzafika pa 0.20mm kufika pa 0.13mm kufika pa 0.08mm mpaka 0.005mm kuti akwaniritse zofunikira za SMT ndi phukusi la chip-multi-chip (Mulitichip Package, MCP). Chifukwa chake, matekinoloje otsatirawa amafunikira:

①Kugwiritsa ntchito zojambula zamkuwa zoonda kapena zowonda kwambiri (<18um) gawo lapansi ndi ukadaulo wamankhwala apamwamba.

②Kugwiritsa ntchito filimu yowonda kwambiri komanso njira yonyowa yowotchera, filimu yowonda komanso yabwino yowuma imatha kuchepetsa kupotoza kwa mzere ndi zolakwika. Kanema wonyowa amatha kudzaza mpweya pang'ono, kukulitsa mawonekedwe omatira, ndikuwongolera kukhulupirika kwa waya ndi kulondola.

③Electrodeposited photoresist (ED) imagwiritsidwa ntchito. Makulidwe ake amatha kuyendetsedwa mumitundu ya 5 ~ 30/um, yomwe imatha kupanga mawaya abwino kwambiri. Ndikoyenera makamaka kufupikitsa mphete m'lifupi, palibe mphete m'lifupi ndi plating yodzaza ndi mbale. Pakadali pano, pali mizere yopitilira khumi yopanga ED padziko lapansi.

④Landirani ukadaulo wowunikira kuwala kofananira. Popeza kuwala kofananirako kungathe kugonjetsa chikoka cha kusiyana kwa mzere wa mzere chifukwa cha kuwala kwa oblique kwa gwero la kuwala kwa "point", waya wabwino wokhala ndi mzere wolondola ndi m'mphepete mwake angapezeke. Komabe, zida zowonetsera zofananira ndizokwera mtengo, zimafunikira ndalama zambiri, ndipo zimafunikira kugwira ntchito pamalo aukhondo kwambiri.

⑤Landirani ukadaulo wodziwikiratu. Tekinoloje iyi yakhala njira yofunika kwambiri yodziwira popanga mawaya abwino ndipo ikulimbikitsidwa, kugwiritsidwa ntchito ndikupangidwa mwachangu.

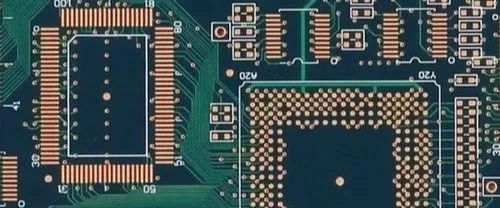

2.Tekinoloje ya Micropore

Mabowo ogwira ntchito a matabwa osindikizidwa opangidwa pamwamba amagwiritsidwa ntchito makamaka pogwirizanitsa magetsi, zomwe zimapangitsa kugwiritsa ntchito teknoloji ya micro-hole kukhala yofunika kwambiri. Kugwiritsa ntchito zida wamba kubowola ndi CNC pobowola makina kubala mabowo ting'onoting'ono ndi zolephera zambiri ndi kukwera mtengo.

Choncho, matabwa osindikizira apamwamba kwambiri amapangidwa makamaka ndi mawaya abwino kwambiri ndi mapepala. Ngakhale zotsatira zazikulu zapezeka, kuthekera kwawo kuli kochepa. Kupititsa patsogolo kachulukidwe (monga mawaya osakwana 0.08 mm), mtengo wakwera kwambiri Chifukwa chake, ma pores ang'onoang'ono amagwiritsidwa ntchito kukonza kachulukidwe.

M'zaka zaposachedwa, zopambana zapangidwa muukadaulo wamakina obowola a CNC ndi tinthu tating'onoting'ono, kotero ukadaulo wa microhole wakula mwachangu. Ichi ndiye chodziwika bwino kwambiri pakupanga kwaposachedwa kwa PCB.

M'tsogolomu, ukadaulo wopangira mabowo ang'onoang'ono udzadalira makina obowola apamwamba a CNC ndi mitu yaying'ono yabwino. Mabowo ang'onoang'ono opangidwa ndi ukadaulo wa laser akadali otsika kuposa mabowo ang'onoang'ono opangidwa ndi makina obowola a CNC potengera mtengo ndi mtundu wa dzenje.

① CNC pobowola makina

Pakali pano, CNC pobowola makina luso wapanga yopambana ndi kupita patsogolo. Ndipo anapanga mbadwo watsopano wa CNC pobowola makina yodziwika ndi kubowola mabowo ting'onoting'ono.

Kuchita bwino kwa kubowola mabowo ang'onoang'ono (osakwana 0.50mm) m'makina obowola ang'onoang'ono ndi 1 nthawi yayitali kuposa makina ochiritsira a CNC, osalephera pang'ono, ndipo liwiro ndi 11-15r / min; Mabowo ang'onoang'ono a 0.1-0.2mm amatha kubowoleredwa. Chobowola chaching'ono chapamwamba kwambiri chimatha kubowoleredwa poyika mbale zitatu (1.6mm/chidutswa).

Chobowola chikasweka, chimatha kuyimitsa ndikuwonetsa momwe chilili, chosinthira chobowolacho ndikuwunika m'mimba mwake (laibulale yazida imatha kukhala ndi zidutswa mazana), ndipo imatha kuwongolera mtunda wokhazikika ndi kuya kwa nsonga yobowola. mbale yophimba, kuti mabowo akhungu athe kubowola , Sitingabowole tebulo.

Gome la makina obowola a CNC amatengera khushoni ya mpweya ndi mtundu wa maginito othamangitsa, omwe amayenda mwachangu, mopepuka komanso molondola popanda kukanda tebulo. Makina obowola oterowo ndi otchuka kwambiri, monga Mega 4600 ochokera ku Prurite ku Italy, Excellon 2000 mndandanda ku United States, ndi zinthu za m'badwo watsopano monga Switzerland ndi Germany.

②Palidi zovuta zambiri pakubowola makina ochiritsira a CNC ndi tizidutswa toboola mabowo ang'onoang'ono. Zalepheretsa kupita patsogolo kwaukadaulo wa micro-hole, kotero kukokoloka kwa laser kwalandira chidwi, kafukufuku ndikugwiritsa ntchito.

Koma pali cholakwika chakupha, ndiko kuti, kupanga mabowo a nyanga, omwe amakhala ovuta kwambiri pamene makulidwe a bolodi akuwonjezeka. Kuphatikizidwa ndi kutentha kwakukulu kwa kutentha kwa mpweya (makamaka matabwa amitundu yambiri), moyo ndi kukonza kwa magetsi, kubwereza kubwereza kwa mabowo otsekedwa, ndi ndalama, kukwezedwa ndi kugwiritsa ntchito mabowo ang'onoang'ono m'magulu osindikizidwa ndizochepa.

Komabe, mabowo opangidwa ndi laser amagwiritsidwabe ntchito pazakudya zoonda kwambiri, makamaka muukadaulo wa MCM-L high-density interconnect (HDI), monga mabowo opangidwa ndi filimu ya poliyesitala ndikuyika zitsulo mu MCMS (ukadaulo wa Sputtering) umagwiritsidwa ntchito kuphatikiza ndipamwamba. - kulumikizana kwa density.

Mapangidwe a maenje okwiriridwa m'mapulani apamwamba kwambiri olumikizana ndi ma multilayer okhala ndi zibowo zokwiriridwa ndi akhungu angagwiritsidwenso ntchito. Komabe, chifukwa cha chitukuko ndi luso lamakono la makina obowola a CNC ndi ma micro-bowola, adalimbikitsidwa ndikugwiritsidwa ntchito mwamsanga.

Chifukwa chake, kugwiritsa ntchito kubowola kwa laser pama board ozungulira okwera sikungapange malo apamwamba. Koma m’dera lina muli malo.

③ kukwiriridwa, akhungu, ukadaulo wamabowo wokwiriridwa, akhungu, ukadaulo wophatikizira pamabowo ndi njira yofunikira yowonjezerera kachulukidwe ka mabwalo osindikizidwa.

Nthawi zambiri, maenje okwiriridwa ndi osawona ndi timabowo tating'ono. Kuwonjezera kuchuluka kwa mawaya pa bolodi, anakwiriridwa ndi mabowo akhungu ntchito "pafupi" inter-wosanjikiza interconnection, amene kwambiri kuchepetsa chiwerengero cha kudzera mabowo anapanga ndi kudzipatula mbale atakhala nawonso kwambiri Kuchepetsa, potero kuonjezera chiwerengero cha mawaya ogwira ntchito ndi inter-wosanjikiza zolumikizira mu bolodi, ndi kuonjezera kachulukidwe interconnections.

Chifukwa chake, bolodi lamitundu yambiri kuphatikiza ndi kukwiriridwa, akhungu, ndi maenje ali ndi kachulukidwe kachulukidwe kasachepera 3 kuposa mawonekedwe a bolodi okhazikika pamiyendo yofanana ndi kuchuluka kwa zigawo. Ngati m'manda, akhungu, ndi Kukula kwa bolodi losindikizidwa pamodzi ndi mabowo kudzachepetsedwa kwambiri kapena chiwerengero cha zigawo chidzachepetsedwa kwambiri.

Chifukwa chake, m'mabodi osindikizidwa okhala ndi kachulukidwe kapamwamba, matekinoloje okwiriridwa ndi akhungu akugwiritsidwa ntchito mochulukira, osati pamapepala osindikizidwa apamakompyuta akulu ndi zida zoyankhulirana, komanso m'mafakitale ndi mafakitale. Amagwiritsidwanso ntchito kwambiri m'munda, ngakhale m'ma board ena owonda, monga PCMCIA, Smard, IC makadi ndi matabwa ena owonda asanu ndi limodzi.

Ma board ozungulira osindikizidwa okhala ndi mabowo okwiriridwa komanso osawona nthawi zambiri amamalizidwa ndi njira yopangira "sub-board", zomwe zikutanthauza kuti zitha kumalizidwa pambuyo pa mbale zambiri zopondereza, kubowola, kubowola mabowo, ndi zina zambiri, kotero kuyika bwino ndikofunikira kwambiri.