Ho nepahala ho phahameng ha boto ea potoloho ho bolela ho sebelisoa ha mela e metle ka bophara / sebaka, likoti tse nyenyane, bophara bo fokolang ba selikalikoe (kapa ha ho na bophara ba selikalikoe), le likoti tse patiloeng le tse foufetseng ho finyella boima bo phahameng.

Ho nepahala ho phahameng ho bolela sephetho sa "tšesaane, tse nyane, tse tšesaane, tse tšesaane" li tla tlisa litlhoko tse nepahetseng tse phahameng, ho nka bophara ba mohala e le mohlala: bophara ba mohala oa 0.20mm, ho latela melao ea ho hlahisa 0.16 ~ 0.24mm joalo ka ba tšoanelehang, phoso ke (0.20±0.04) mm; le bophara ba mohala oa 0.10 mm, phoso ke (0.1±0.02) mm ka tsela e ts'oanang. Ho hlakile hore ho nepahala ha ho qetela ho imenne habeli, joalo-joalo ha ho thata ho utloisisa, kahoo ho nepahala ho phahameng hoa hlokahala Ha ho sa buisanoa ka thoko, empa ke bothata bo hlahelletseng ho theknoloji ea tlhahiso.

Theknoloji ea 1.Fine terata

Nakong e tlang, bophara ba mela e phahameng haholo e tla tloha ho 0.20mm ho isa 0.13mm ho isa 0.08mm ho isa 0.005mm ho fihlela litlhoko tsa SMT le sephutheloana sa li-chip tse ngata (Mulitichip Package, MCP). Ka hona, ho hlokahala theknoloji e latelang:

① Ho sebelisa foil ea koporo e tšesaane kapa e tšesaane haholo (<18um) le theknoloji e ntle ea kalafo ea holim'a metsi.

②Ho sebelisa filimi e tšesaane e omeletseng le mokhoa oa ho lamination oa metsi, filimi e tšesaane le e ntle ea boleng bo botle e ka fokotsa ho sotha ha mela le liphoso. Filimi e metsi e ka tlatsa lekhalo le lenyenyane la moea, ea eketsa khokahanyo ea sebopeho, 'me ea ntlafatsa botšepehi ba mohala le ho nepahala.

③Electrodeposited photoresist (ED) e sebelisoa. Botenya ba eona bo ka laoloa ho tloha ho 5 ~ 30/um, e ka hlahisang lithapo tse ntle tse phethahetseng haholoanyane. E loketse ka ho khetheha bakeng sa bophara bo moqotetsane ba selikalikoe, ha ho na bophara ba selikalikoe le ho penta ka botlalo. Hajoale, ho na le mela e fetang leshome ea tlhahiso ea ED lefatšeng.

④ Sebelisa tekhenoloji ea ho pepeseha mabone a tšoanang. Kaha khanya e ts'oanang ea leseli e ka hlōla tšusumetso ea phapang ea bophara ba mela e bakoang ke leseli le oblique la mohloli oa leseli la "point", terata e ntle e nang le bophara bo nepahetseng ba mela le metse e boreleli e ka fumanoa. Leha ho le joalo, lisebelisoa tsa ho pepeseha tse tšoanang li theko e boima, li hloka matsete a phahameng, 'me li hloka ho sebetsa sebakeng se hloekileng.

⑤ Amohela theknoloji ea othomathike ea ho bona. Theknoloji ena e fetohile mokhoa oa bohlokoa oa ho lemoha ha ho etsoa lithapo tse ntle 'me e ntse e khothaletsoa ka potlako, e sebelisoa le ho ntlafatsoa.

2.Theknoloji ea Micropore

Likoti tse sebetsang tsa mapolanka a hatisitsoeng a holimo-limo li sebelisoa haholo-holo bakeng sa ho hokahanya ha motlakase, e leng se etsang hore tšebeliso ea theknoloji ea micro-hole e be ea bohlokoa haholo. Tšebeliso ea lisebelisoa tse tloaelehileng tsa ho cheka le mechini ea ho cheka ea CNC ho hlahisa likoti tse nyane e na le liphoso tse ngata le litšenyehelo tse phahameng.

Ka hona, liboto tsa potoloho tse hatisitsoeng tse phahameng haholo li entsoe ke likhoele tse ntle le liphaephe. Le hoja liphello tse kholo li fihletsoe, bokhoni ba bona bo lekanyelitsoe. Ho tsoela pele ho ntlafatsa boima ba 'mele (joalo ka lithapo tse ka tlaase ho 0.08 mm), litšenyehelo li phahame haholo Ka hona, li-micro-pores li sebelisetsoa ho ntlafatsa ho teteana.

Lilemong tsa morao tjena, ho entsoe katleho ho theknoloji ea mechine ea ho cheka ea CNC le li-micro-bits, kahoo theknoloji ea micro-hole e tsoetse pele ka potlako. Ena ke karolo e ka sehloohong e hlahelletseng tlhahisong ea hajoale ea PCB.

Nakong e tlang, theknoloji ea ho etsa likoti tse nyenyane e tla itšetleha haholo ka mechine ea ho cheka ea CNC e tsoetseng pele le li-micro-heads tse ntle. Likoti tse nyane tse entsoeng ke theknoloji ea laser li ntse li le tlase ho likoti tse nyane tse entsoeng ke mechini ea ho phunya ea CNC ho latela pono ea litšenyehelo le boleng ba lesoba.

① mochini oa ho cheka oa CNC

Hona joale, theknoloji ea mochine oa ho cheka oa CNC e entse tsoelo-pele e ncha le tsoelo-pele. Mme e thehile mochini o mocha oa mochini oa ho cheka oa CNC o khetholloang ka ho phunya masoba a manyane.

Bokhoni ba ho cheka likoti tse nyenyane (tse ka tlase ho 0.50mm) ka mechine ea ho phunya likoti tse nyenyane ke makhetlo a 1 ho feta a mechine e tloaelehileng ea ho phunya CNC, e nang le liphoso tse fokolang, 'me lebelo ke 11-15r / min; 0.1-0.2mm likoti tse nyane li ka phunngoa. Sebopa se senyane sa boleng bo holimo se ka chekoa ka ho bokella lipoleiti tse tharo (1.6mm/sekotoana).

Ha boro e robeha, e ka ema 'me ea tlaleha boemo ka bo eona, ea nkela sebaka sa ho cheka ka bo eona ebe e lekola bophara (laebrari ea lisebelisoa e ka amohela likotoana tse makholo), 'me e khona ho laola ka bohona bohole bo sa feleng le botebo ba ho phunya ba ntlha ea ho phunya. sekoahelo sekoahelo, e le hore likoti tse foufetseng li ka phunngoa , E ke ke ea phunya tafole.

Tafole ea mochini oa ho phunya oa CNC o amohela mosamo oa moea le mofuta oa "magnetic levitation", o tsamaeang ka potlako, o bobebe le ka nepo ntle le ho hoa tafole. Mechini e joalo ea ho cheka hona joale e tumme haholo, joalo ka Mega 4600 e tsoang Prurite Italy, Excellon 2000 letoto la United States, le lihlahisoa tse ncha tse kang Switzerland le Jeremane.

②Ho na le mathata a mangata ka ho cheka metjhini e tloaelehileng ea CNC le likotoana tsa ho phunya masoba a manyane. E sitisitse tsoelopele ea thekenoloji ea micro-hole, kahoo khoholeho ea laser e fumane tlhokomelo, lipatlisiso le tšebeliso.

Empa ho na le phoso e bolaeang, ke hore, ho thehoa ha likoti tsa lenaka, tse fetohang tse tebileng haholoanyane ha botenya ba boto bo ntse bo eketseha. Ho kopantsoe le tšilafalo e phahameng ea mocheso (haholo-holo liboto tse nang le likarolo tse ngata), bophelo le tlhokomelo ea mehloli ea leseli, ho pheta-pheta ho nepahala ha masoba a kolobisitsoeng, le litšenyehelo, ho phahamisa le ho sebelisoa ha likoti tse nyenyane ka har'a liboto tse hatisitsoeng li fokotsehile.

Leha ho le joalo, likoti tse kentsoeng ka laser li ntse li sebelisoa ho li-microplates tse tšesaane tse phahameng haholo, haholo-holo ho theknoloji ea MCM-L high-density interconnect (HDI), joalo ka masoba a kentsoeng filimi ea polyester le ho kenya tšepe ho MCMS (theknoloji ea Sputtering) e sebelisoa hammoho le maemo a holimo. -maqhama a mangata.

Ho thehoa ha masoba a patiloeng ka mapolanka a mangata a mangata a hokahaneng a nang le likoti tse patiloeng le tse foufetseng le tsona li ka sebelisoa. Leha ho le joalo, ka lebaka la tsoelo-pele le tsoelo-pele ea theknoloji ea mechine ea ho cheka ea CNC le li-micro-drill, li ile tsa khothaletsoa ka potlako le ho sebelisoa.

Ka hona, ts'ebeliso ea ho phunya laser ka holim'a liboto tsa potoloho ea holim'a thaba e ke ke ea theha boemo bo ka sehloohong. Empa ho ntse ho na le sebaka sebakeng se itseng.

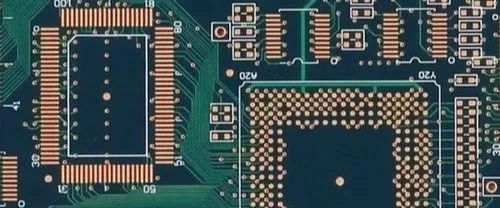

③ e patiloeng, e foufetseng, theknoloji ea lesoba e patiloeng, e foufetseng, theknoloji ea motsoako oa lesoba ke mokhoa oa bohlokoa oa ho eketsa bongata ba lipotoloho tse hatisitsoeng.

Ka kakaretso, likoti tse patiloeng le tse foufetseng ke masoba a manyenyane. Ntle le ho eketsa palo ea lithapo holim'a boto, likoti tse patiloeng le tse foufetseng li sebelisa "haufi" li-inter-layer interconnection, tse fokotsang haholo palo ea ka likoti tse entsoeng le ho itšehla thajana ho tla boela ho fokotsehe haholo. palo ea lithapo tse sebetsang hantle le likhokahano tse lipakeng tsa boto, le ho eketsa bongata ba likhokahano.

Ka hona, boto ea li-multi-layer e kopantsoeng le masoba a patiloeng, a foufetseng, le ka-ho-ho-ho na le khokahanyo ea likhokahanyo bonyane makhetlo a 3 ho feta a boto e tloaelehileng e tletseng lesoba ka boholo bo lekanang le palo ea lihlopha. Haeba e patoa, e foufetse, 'me Boholo ba boto e hatisitsoeng bo kopantsoeng le masoba bo tla fokotsoa haholo kapa palo ea lihlopha e tla fokotseha haholo.

Ka hona, ka mapolanka a hatisitsoeng a holimo-limo a holimo-limo, theknoloji e patiloeng le e foufetseng e ntse e sebelisoa ka ho eketsehileng, eseng feela ka liboto tse hatisitsoeng holim'a lik'homphieutha tse kholo le lisebelisoa tsa puisano, empa hape le lits'ebetsong tsa sechaba le tsa indasteri. E boetse e sebelisoa haholo tšimong, esita le libotong tse ling tse tšesaane, tse kang likarete tse fapaneng tsa PCMCIA, Smart, IC le liboto tse ling tse tšesaane tse nang le likarolo tse tšeletseng.

Liboto tsa potoloho tse hatisitsoeng tse nang le meaho ea likoti tse patiloeng le tse foufetseng ka kakaretso li phethoa ka mokhoa oa tlhahiso ea "sub-board", e bolelang hore e ka phethoa ka mor'a lipoleiti tse ngata tse hatellang, ho phunya, ho pata likoti, joalo-joalo, kahoo boemo bo nepahetseng ke ba bohlokoa haholo.