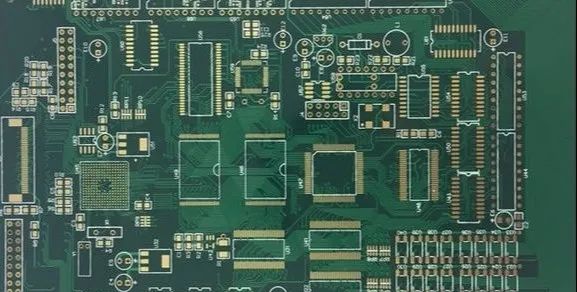

Babban madaidaicin allon kewayawa yana nufin yin amfani da fa'ida mai kyau / tazara, ƙananan ramuka, kunkuntar zobe nisa (ko babu faɗin zobe), da binne da makafi don cimma babban yawa.

Babban madaidaicin yana nufin sakamakon "bakin ciki, ƙarami, kunkuntar, bakin ciki" ba makawa zai kawo madaidaicin buƙatun, ɗaukar faɗin layin azaman misali: nisa layin 0.20mm, bisa ga ƙa'idodi don samar da 0.16 ~ 0.24mm kamar yadda ya cancanta, kuskuren shine (0.20± 0.04) mm; da layin layin 0.10 mm, kuskuren shine (0.1 ± 0.02) mm a cikin hanya guda. Babu shakka daidaito na karshen yana ninka sau biyu, kuma haka ba shi da wahala a fahimta, don haka ana buƙatar babban daidaito Ba a tattauna daban ba, amma babbar matsala ce a fasahar samarwa.

1.Fine fasahar waya

A nan gaba, babban layin nisa / nisa zai kasance daga 0.20mm zuwa 0.13mm zuwa 0.08mm zuwa 0.005mm don saduwa da buƙatun SMT da kunshin guntu da yawa (Muliticip Package, MCP). Don haka, ana buƙatar waɗannan fasahohin:

①Amfani da bakin ciki ko matsananci-bakin ciki tagulla tsare (<18um) substrate da lafiya surface jiyya fasahar.

②Yin amfani da fim ɗin busassun bushewa da rigar lamination tsari, bakin ciki da ingancin busassun fim mai kyau na iya rage karkatar da faɗin layi da lahani. Fim ɗin rigar na iya cika ɗan ƙaramin iska, haɓaka mannewa, da haɓaka amincin waya da daidaito.

Ana amfani da Electrodeposited photoresist (ED). Ana iya sarrafa kauri a cikin kewayon 5 ~ 30 / um, wanda zai iya samar da mafi kyawun wayoyi masu kyau. Ya dace musamman don kunkuntar nisa zobe, babu nisa zobe da cikakken plating. A halin yanzu, akwai layukan samar da ED sama da goma a duniya.

④Kwantar da fasahar fallasa haske mai layi daya. Tun da hasken haske mai kama da juna zai iya shawo kan tasirin bambancin nisa na layi wanda ya haifar da hasken da ya dace na tushen hasken "ma'ana", za a iya samun waya mai kyau tare da daidaitattun layin layi da gefuna masu santsi. Duk da haka, kayan aiki masu kama da juna suna da tsada, yana buƙatar babban zuba jari, kuma yana buƙatar aiki a cikin tsaftataccen yanayi.

⑤Kwantar da fasahar gano gani ta atomatik. Wannan fasaha ta zama hanyar ganowa da babu makawa wajen samar da wayoyi masu kyau kuma ana haɓakawa cikin sauri, amfani da su da haɓakawa.

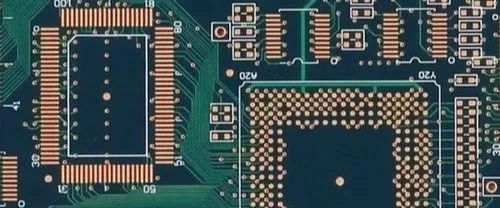

2.Micropore fasaha

Ana amfani da ramukan aiki na allunan bugu da aka ɗora a sama don haɗa haɗin lantarki, wanda ke sa aikace-aikacen fasahar ƙaramin rami ya fi mahimmanci. Amfani da kayan hakowa na al'ada da na'urorin hakowa na CNC don samar da ƙananan ramuka yana da gazawa da yawa da tsada.

Don haka, manyan allunan da'ira da aka buga mafi yawa ana yin su ta mafi kyawun wayoyi da pads. Ko da yake an sami sakamako mai girma, ƙarfinsu yana da iyaka. Don ƙara haɓaka haɓaka (kamar wayoyi da ke ƙasa da 0.08 mm), farashin ya karu sosai Saboda haka, ana amfani da ƙananan pores don inganta haɓaka.

A cikin 'yan shekarun nan, an sami ci gaba a cikin fasaha na injinan hakowa na CNC da micro-bits, don haka fasahar micro-rami ta haɓaka cikin sauri. Wannan shine babban abin da ya fi fice a cikin samar da PCB na yanzu.

A nan gaba, fasahar samar da ƙananan ramuka za ta dogara ne akan injunan hakowa na CNC na ci gaba da ƙananan ƙananan shugabannin. Ƙananan ramukan da fasahar Laser ta samar har yanzu ba su da ƙasa da ƙananan ramukan da na'urorin hakowa na CNC suka kafa daga mahangar farashi da ingancin rami.

①CNC hakowa inji

A halin yanzu, fasahar hakowa ta CNC ta sami sabbin ci gaba da ci gaba. Kuma kafa sabon ƙarni na na'ura mai hakowa CNC halin da hako kananan ramuka.

Ingantacciyar haɓakar ƙananan ramuka (kasa da 0.50mm) a cikin injunan hakowa na micro-rami shine sau 1 sama da na na'urorin hakowa na CNC na al'ada, tare da ƙarancin gazawa, kuma saurin shine 11-15r / min; 0.1-0.2mm micro ramukan za a iya hakowa. Za'a iya hako ɗan ƙaramin ɗanɗano mai inganci mai inganci ta hanyar tara faranti uku (1.6mm/ yanki).

Lokacin da rawar sojan ta karye, zai iya tsayawa ta atomatik kuma ya ba da rahoton matsayin, ta atomatik maye gurbin rawar sojan ta atomatik kuma duba diamita (laburaren kayan aiki na iya ɗaukar ɗaruruwan guda), kuma yana iya sarrafa madaidaiciyar nesa da zurfin hakowa na tukwici kuma ta atomatik. farantin murfin, don haka za a iya toshe ramukan makafi , Ba zai yi rawar jiki ba.

Tebur na injin hakowa na CNC yana ɗaukar matashin iska da nau'in levitation na maganadisu, wanda ke motsawa cikin sauri, mai sauƙi da ƙari daidai ba tare da tabo teburin ba. Irin waɗannan injunan hakowa a halin yanzu sun shahara sosai, kamar Mega 4600 daga Prurite a Italiya, jerin Excellon 2000 a Amurka, da sabbin kayayyaki irin su Switzerland da Jamus.

②Hakika akwai matsaloli da yawa tare da Laser hakowa na al'ada CNC hako inji da ragowa to hako micro ramuka. Ya hana ci gaban fasahar micro-rami, don haka zaizayar laser ta sami kulawa, bincike da aikace-aikace.

Amma akwai mummunar lahani, wato, samuwar ramukan ƙaho, wanda ya zama mafi tsanani yayin da kauri daga cikin jirgi ya karu. Haɗe tare da ƙazantar zubar da zafin jiki mai girma (musamman allunan Layer Layer), rayuwa da kiyaye hanyoyin haske, maimaita daidaitattun ramuka, da farashi, haɓakawa da aikace-aikacen ƙananan ramuka a cikin allunan da aka buga suna iyakance.

Duk da haka, Laser etched ramukan har yanzu ana amfani da a cikin bakin ciki high-yawa microplates, musamman a MCM-L high-yawa interconnect (HDI) fasaha, kamar polyester film etched ramukan da karfe jijjiga a MCMS (Sputtering fasaha) ana amfani da a hade tare da high. - yawa interconnects.

Haka kuma ana iya amfani da samuwar ramukan da aka binne a cikin manyan alluna masu haɗin haɗin gwiwa tare da tsarin rami da aka binne da makafi. Duk da haka, saboda ci gaba da ci gaban fasaha na injinan hakowa na CNC da ƙananan hakowa, an inganta su da sauri kuma an yi amfani da su.

Saboda haka, aikace-aikace na Laser hakowa a surface Dutsen kewaye allon ba zai iya samar da wani rinjaye matsayi. Amma har yanzu akwai wuri a wani yanki.

③ binne, makafi, fasaha ta rami da aka binne, makafi, fasahar haɗin ramuka kuma hanya ce mai mahimmanci don ƙara yawan da'irori da aka buga.

Gabaɗaya, ramukan da aka binne da makafi ƙananan ramuka ne. Baya ga ƙara yawan wayoyi a kan allo, ramukan da aka binne da makafi suna amfani da haɗin gwiwar "mafi kusa" tsakanin Layer Layer, wanda ke rage yawan adadin ta ramukan da aka kafa kuma saitin keɓewa zai zama Ragewa sosai, ta haka zai ƙara haɓaka. adadin ingantattun hanyoyin haɗin yanar gizo da haɗin kai a cikin allo, da haɓaka yawan haɗin haɗin gwiwa.

Sabili da haka, allon-layi mai yawa da aka haɗa tare da binne, makafi, da ramukan ramuka yana da haɗin haɗin haɗin kai na akalla sau 3 fiye da na tsarin tsarin katako mai cike da ramuka na al'ada a girman girman da adadin yadudduka. Idan an binne, makafi, da Girman allon da aka buga tare da ramuka zai ragu sosai ko kuma adadin yadudduka zai ragu sosai.

Don haka, a cikin manyan allunan da aka ɗora da su, ana ƙara amfani da fasahar rami da aka binne da makafi, ba kawai a cikin allunan da aka ɗora a cikin manyan kwamfutoci da kayan sadarwa ba, har ma a aikace-aikacen farar hula da masana'antu. Har ila yau, an yi amfani da shi sosai a cikin filin, har ma a cikin wasu ƙananan alluna, kamar PCMCIA daban-daban, Smard, IC cards da sauran ƙananan allunan Layer shida.

The buga kewaye allon tare da binne da makafi tsarin da aka gama gaba ɗaya ta hanyar samar da "sub-board", wanda ke nufin cewa za a iya kammala bayan da yawa latsa faranti, hakowa, rami plating, da dai sauransu, don haka daidai matsayi yana da muhimmanci sosai .