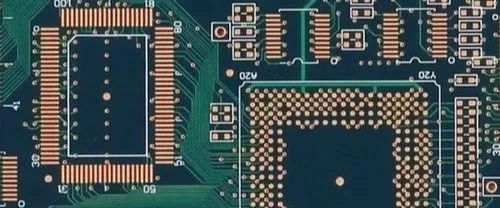

The high precision of the circuit board refers to the use of fine line width/spacing, micro holes, narrow ring width (or no ring width), and buried and blind holes to achieve high density.

The high precision refers to the result of “thin, small, narrow, thin” will inevitably bring high precision requirements, taking the line width as an example: 0.20mm line width, according to the regulations to produce 0.16 ~ 0.24mm as qualified, the error is (0.20±0.04) mm; and the line width of 0.10 mm, the error is (0.1±0.02) mm in the same way. Obviously the accuracy of the latter is doubled, and so on is not difficult to understand, so high precision is required No longer discussed separately, but it is a prominent problem in production technology.

1.Fine wire technology

In the future, the high-density line width/spacing will be from 0.20mm to 0.13mm to 0.08mm to 0.005mm to meet the requirements of SMT and multi-chip package (Mulitichip Package, MCP). Therefore, the following technologies are required:

①Using thin or ultra-thin copper foil (<18um) substrate and fine surface treatment technology.

②Using thinner dry film and wet lamination process, thin and good quality dry film can reduce line width distortion and defects. Wet film can fill a small air gap, increase interface adhesion, and improve wire integrity and accuracy.

③Electrodeposited photoresist (ED) is used. Its thickness can be controlled in the range of 5 ~ 30/um, which can produce more perfect fine wires. It is especially suitable for narrow ring width, no ring width and full-plate plating. At present, there are more than ten ED production lines in the world.

④Adopt parallel light exposure technology. Since the parallel light exposure can overcome the influence of the line width variation caused by the oblique light of the “point” light source, a fine wire with accurate line width and smooth edges can be obtained. However, the parallel exposure equipment is expensive, requires high investment, and requires working in a high-cleanness environment.

⑤Adopt automatic optical detection technology. This technology has become an indispensable means of detection in the production of fine wires and is being rapidly promoted, applied and developed.

2.Micropore technology

The functional holes of surface-mounted printed boards are mainly used for electrical interconnection, which makes the application of micro-hole technology more important. The use of conventional drill bit materials and CNC drilling machines to produce tiny holes has many failures and high costs.

Therefore, the high-density printed circuit boards are mostly made by the finer wires and pads. Although great results have been achieved, their potential is limited. To further improve the density (such as wires less than 0.08 mm), the cost has risen sharply Therefore, micro-pores are used to improve the densification.

In recent years, breakthroughs have been made in the technology of CNC drilling machines and micro-bits, so the micro-hole technology has developed rapidly. This is the main outstanding feature in the current PCB production.

In the future, the technology of forming micro-holes will mainly rely on advanced CNC drilling machines and fine micro-heads. The small holes formed by laser technology are still inferior to the small holes formed by CNC drilling machines from the viewpoint of cost and hole quality.

①CNC drilling machine

At present, CNC drilling machine technology has made new breakthroughs and progress. And formed a new generation of CNC drilling machine characterized by drilling tiny holes.

The efficiency of drilling small holes (less than 0.50mm) in micro-hole drilling machines is 1 times higher than that of conventional CNC drilling machines, with fewer failures, and the speed is 11-15r/min; 0.1-0.2mm micro holes can be drilled. The high-quality high-quality small drill bit can be drilled by stacking three plates (1.6mm/piece).

When the drill bit breaks, it can automatically stop and report the position, automatically replace the drill bit and check the diameter (the tool library can accommodate hundreds of pieces), and can automatically control the constant distance and drilling depth of the drill tip and the cover plate, so that blind holes can be drilled , Will not drill the table.

The table of CNC drilling machine adopts air cushion and magnetic levitation type, which moves faster, lighter and more accurately without scratching the table. Such drilling machines are currently very popular, such as Mega 4600 from Prurite in Italy, Excellon 2000 series in the United States, and new generation products such as Switzerland and Germany.

②There are indeed many problems with laser drilling conventional CNC drilling machines and bits to drill micro holes. It has hindered the progress of micro-hole technology, so laser erosion has received attention, research and application.

But there is a fatal flaw, that is, the formation of horn holes, which becomes more serious as the thickness of the board increases. Coupled with high temperature ablation pollution (especially multi-layer boards), the life and maintenance of light sources, the repeat accuracy of etched holes, and costs, the promotion and application of micro holes in printed boards are limited.

However, laser etched holes are still used in thin high-density microplates, especially in MCM-L high-density interconnect (HDI) technology, such as polyester film etched holes and metal deposition in M.C.MS (Sputtering technology) is used in combination with high-density interconnects.

The formation of buried holes in high-density interconnected multilayer boards with buried and blind hole structures can also be applied. However, due to the development and technological breakthroughs of CNC drilling machines and micro-drills, they were quickly promoted and applied.

Therefore, the application of laser drilling in surface mount circuit boards cannot form a dominant position. But there is still a place in a certain area.

③ buried, blind, through-hole technology buried, blind, through-hole combination technology is also an important way to increase the density of printed circuits.

Generally, the buried and blind holes are tiny holes. In addition to increasing the number of wiring on the board, the buried and blind holes use the “closest” inter-layer interconnection, which greatly reduces the number of through holes formed and the isolation plate setting will also be greatly Reduction, thereby increasing the number of effective wiring and inter-layer interconnections in the board, and increasing the density of interconnections.

Therefore, the multi-layer board combined with buried, blind, and through-holes has a interconnection density of at least 3 times higher than that of the conventional full-through-hole board structure at the same size and number of layers. If buried, blind, and The size of the printed board combined with through holes will be greatly reduced or the number of layers will be significantly reduced.

Therefore, in high-density surface-mounted printed boards, buried and blind hole technologies are increasingly used, not only in surface-mounted printed boards in large computers and communication equipment, but also in civil and industrial applications. It has also been widely used in the field, even in some thin boards, such as various PCMCIA, Smard, IC cards and other thin six-layer boards.

The printed circuit boards with buried and blind hole structures are generally completed by the “sub-board” production method, which means that it can be completed after many pressing plates, drilling, hole plating, etc., so precise positioning is very important .